project H:Realization

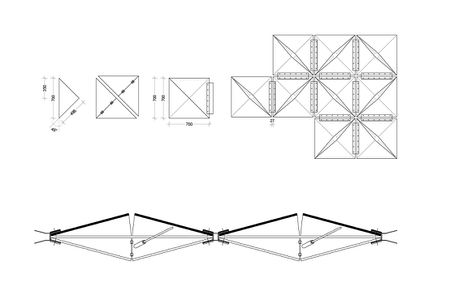

DETAILS

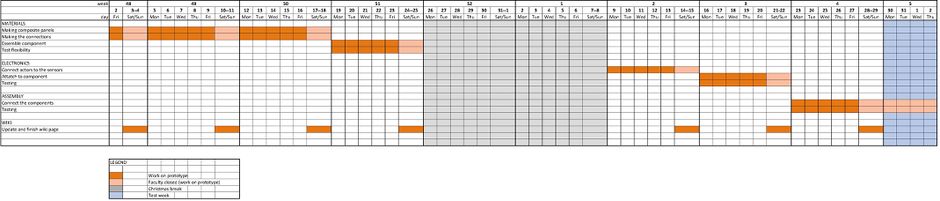

TIME-LINE AND MATERIALS

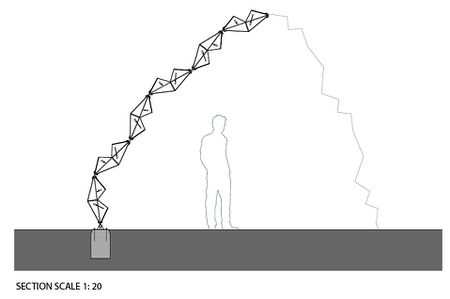

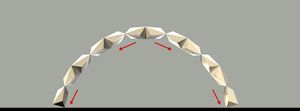

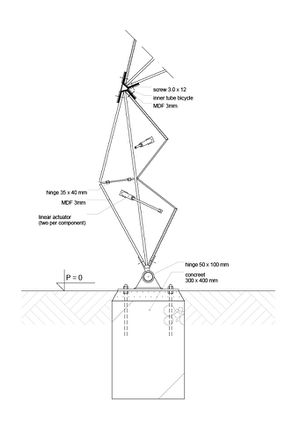

STRUCTURE

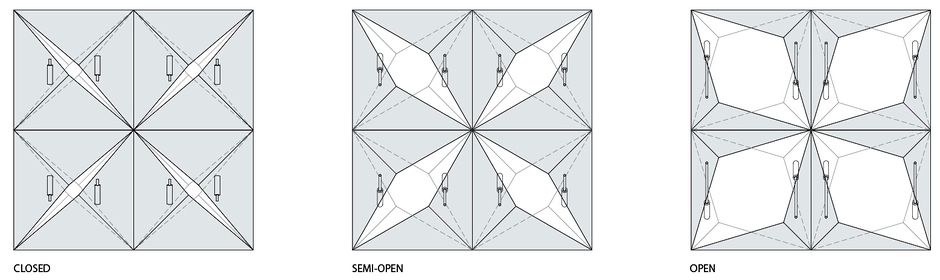

Our load bearing structure will be created by the component itself. When a component opens it is deforming, the outlines change. What first seemed to be the biggest challenge of our component, became very useful. When the component changes its outlines it creates tension in the components surrounding it. By anchoring the outlines of the complete structure and opening the components we can create a stiff structure. By adjusting the size of the openings by the actuators we can control the shape.

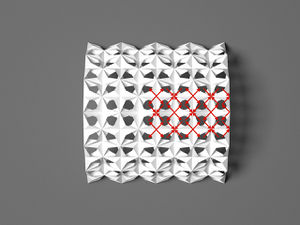

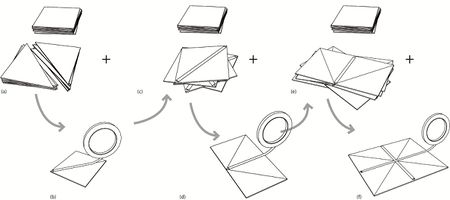

In parallel to digital explorations, we built a prototype from cardboard panels. In order to ease the assembly process, we join component elements by taping them together. In this case, we utilize a 20mm reinforced tape. The tape is in turn replacing a rotational movement that otherwise would be possible by a hinging system. However, what becomes important is the sequence in which these pieces are group together to ease the assembly process. Each component is divided into 8 triangular pieces. In this case, they are grouped into components and assembled as such. Each pair of elements is able to rotate 180 degrees. A folding element make up a component. This component type is then made up of four ridges and four valleys in the shape of triangles. As a component these triangular pairs are capable of expanding and contracting independently from its neighboured pairs. The rotational freedom from one element pair allows for local control within a component. Therefore, gaining local control over an entire surface area.

RELATIONSHIPS

ATOMS

Still our atom is in his origin state no collaboration has taken place. As to the relations to other atoms, atom 3 is on the same level with their component. The research we both did is quite different, but the outcome shows similarities .

PROJECTS

Project G is making a platform that can adjust to different functions. This concept is completely different than ours but the similarities are in the components. They also have designed one component they use repeatedly. Making a complex structure out of simple components.