project C:PROTOTYPE

PROTOTYPE

MATERIAL PROGRESS

Materials Research

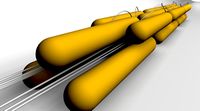

- Inflatable Units

08 December 2011

Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes.

17 December 2011

First test-units arrived. MTB - inner rubber tubes. Material thickness: 1.5mm , Length: 300mm - ..., Diameter: 70mm - ...

18 units Heidenau D21 natural rubber Size: 21" 3.00-3.25 90/90, 80/100

- Frame for Inflatable Units

14 December 2011

First test-sheets arrived. PVC Truck-tarp. Material thickness: 1.5mm , Length: 1600mm, Length: 1000mm

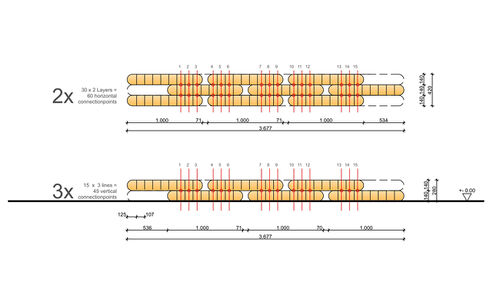

- Connection System

60 units horizontal-connections

45 unit vertical connections

105 connections - total

- Air Pressure System

70 m transparent PVC tubing (outer diameter=10mm)

18 clamps (on tube-valves outer diameter= 8mm)

18 valves (distributor)

1 x 3 way distributor

1 x air compressor

- Pulley System

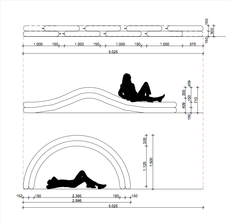

1:1 MODEL PROPOSAL

For the 1:1 model a small portion of the structure will be build: a fragment of the strip that is anchored to the ground.

PROTOTYPE PROGRESS

Material Test

19 December 2011

Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes.

Cap Test

22 December 2011

A different end of the component was designed: a cap. The hugger will be sewn with a sewing machine,

but for the scale model this is not always possible -> it is too small to put under the sewing machine.

The new cap was tested and here under you can find the pictures.

Real size rubber test

22 December 2011

A different end of the component was designed: a cap. The hugger will be sewn with a sewing machine,

but for the scale model this is not always possible -> it is too small to put under the sewing machine.

The new cap was tested and here under you can find the pictures.

Real size component test

10 January 2012

By several experiment result, we defined the final prototype materials and dimensions.

By accumulating the experience of tested components, this testing component is in 1:1 scale to the final product.