project B:Realisation Plan

| Line 9: | Line 9: | ||

---- | ---- | ||

| − | <youtube width="500" height="310" right>IZiKJ1DVMLk</youtube> | + | <youtube width="500" height="310" right> IZiKJ1DVMLk </youtube> |

| + | |||

| + | <youtube width="500" height="310" right> CYjSKhNXqdE </youtube> | ||

| + | |||

| + | |||

| + | |||

| + | <youtube width="500" height="310" right> OdiWhWCHCro </youtube> | ||

| − | |||

Revision as of 18:07, 1 February 2012

HyperPublic : Home / Realisation Plan

YouTube : bad video ID !

YouTube : bad video ID !

YouTube : bad video ID !

aangeven dat we pas echt precies zijn gaan laseren toen we 1op1 hadden gemaakt, daarvoor alleen principes. Heeft voor en nadelen. Want detail niveau had in dit geval enigszins ook in laser gemaakt kunnen worden en dan hadden we misschien al die tabiliteitproblemen precies kunnen aan zien komen.

REFERENTIE CNC FREES IN CONTAINER

dit hieronder kan volgens mij weg

\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

Development path

01 - testing fabrication methods

02 - presenting design ideas and incorporating feedback in design

03 - generate an overview of available materials and making design scalable

04 - testing tolerances and usability scale 1:10 with CNC milling machine (in absence of lasercutter)

05 - generating final 1:10 scale model to present to protoSPACE staff incuding Kas Oosterhuis weeks before final presentation

06 - using feedback to adjust and generate a part of the design scale 1:1 to face final challenges in connections, size and weight

07 - after a 'go' talk to large scale manufacturers in the area to help them sponsor machine time on large scale CNC milling machines

08 - gaining approval by presenting to protoSPACE staff to create the complete project scale 1:1 and showing final calculations

09 - build final design scale 1:1 with sponsoring of milling time by company and only material investment of Hyperbody

10 - taking surveys to compare to survey at the beginning of the semester to see if our goals are met

11 - structure all relevant generated texts, (computer)models and knowledge in a form future users could learn from or can adjust (parts of) the design

Fabrication

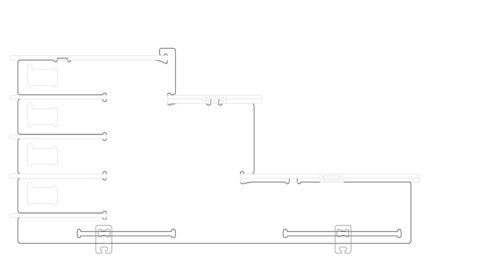

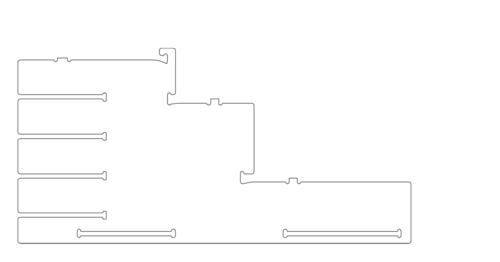

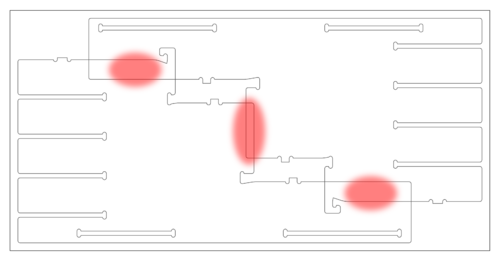

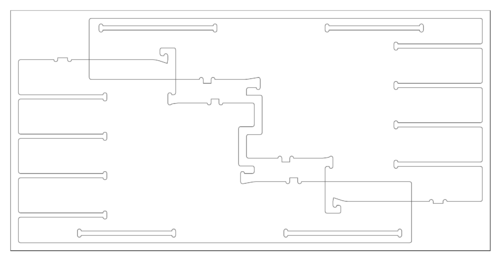

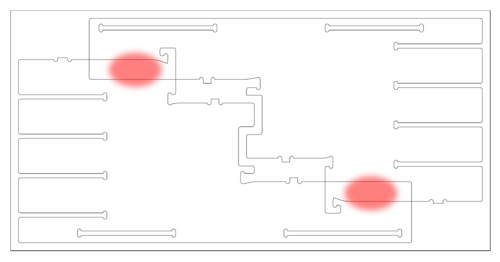

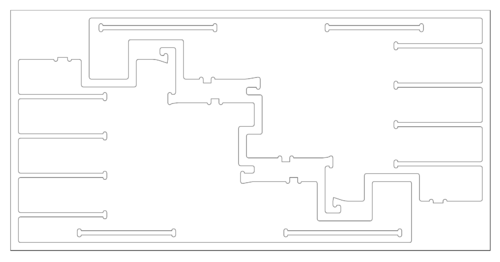

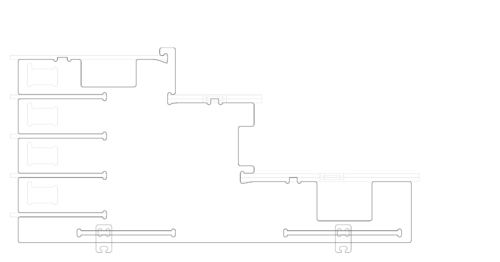

Below is a sequence of images which shows an example of what kind of challenges we face while actually fabricating our design. Therefor the fabricationprocess is an important element in shaping our structural elements.

In the complete design, we have thought about drillhead sizes, wood board thickness and dimensions, scalability and the limits of the CNC milling machine. By making samples of just the connections on 1:10 and 1:1 scale, we have already found out some fabrication tolerances and we will keep working this way between the design and fabrication to create an actual fabricated 1:1 model as an end goal for this MSc1 course.

HyperPublic : Home / Realisation Plan