project C:Linear component

| (32 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | <div style="float: left; width: 1200px; margin-right:40px; text-align:left"> | |

| − | + | ||

| − | + | '''LINEAR COMPONENT '''- brick-like pattern arrangement vs non brick-like pattern arrangement | |

| − | + | <gallery widths="190" heights="200" perrow="5" > | |

| − | File: | + | File:comp04.JPG|'''brick pattern''' - support at one end - structure is self-supporting |

| − | File: | + | File:comp02.JPG|'''brick pattern''' - support at both ends - structure has improved stiffness |

| − | File: | + | File:comp03.JPG|'''non-brick pattern''' - support at one end - structure is almost self-supporting |

| − | + | file:Comp09.JPG|'''both arrangements''' side by side | |

| − | + | file:comp06.jpg|'''curvature comparison''' - at the same length the brick pattern achieves greater curvature | |

</gallery> | </gallery> | ||

| − | + | '''Conclusion:''' | |

| − | + | ||

| − | [[Project C: | + | The brick pattern arrangement is by far superior to the non-brick pattern. The brick pattern has shown improved structural stiffness in comparison with the non-brick pattern. |

| + | <br> | ||

| + | <br> | ||

| + | |||

| + | '''LINEAR COMPONENT - 1:5 scale''' | ||

| + | |||

| + | <gallery widths="190" heights="200" perrow="5" > | ||

| + | |||

| + | File:panty1.JPG|over-inflation of component | ||

| + | File:panty2.JPG|over-inflation results in greater curvature - components are self-supporting | ||

| + | File:panty6.JPG|close-up of the roof inner surface | ||

| + | file:panty5.jpg|close-up of the patch connections and guide-rails for the fabric walls | ||

| + | File:panty3.JPG|detaching the patches creates the guide-rails for the fabric walls | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | '''Conclusion:''' | ||

| + | |||

| + | The addition of a protective mesh has resulted in a greater resistance of the inflatable element to over-pressure. The mesh and inflatable present a similar behavior to the car tire - car tube system. Detaching the patches presents a problem when the fabric walls are always attached to the guide rails. This system for the fabric walls has been currently abandoned. The alternative of attaching the fabric walls directly to the ground cable structure is being considered as a manual option. | ||

| + | |||

| + | |||

| + | '''GRASSHOPPER SIMULATION '''- linear component - the model for the component frame has been implemented in Grasshopper for added flexibility. | ||

| + | |||

| + | <youtube width="350" height="200" left >n_f1jxIKL2I</youtube> | ||

| + | |||

| + | <gallery widths="300" heights="200" perrow="2" > | ||

| + | |||

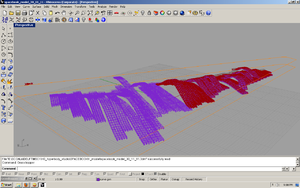

| + | File:g_model.png| Grasshopper model - extremely computational expensive | ||

| + | |||

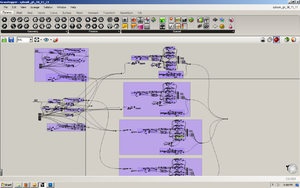

| + | File:g_def.png| Grasshopper definition | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | |||

| + | [[Project C:STRUCTURE|go back to structure page >>]] | ||

| + | |||

| + | </div> | ||

Latest revision as of 12:06, 5 December 2011

LINEAR COMPONENT - brick-like pattern arrangement vs non brick-like pattern arrangement

Conclusion:

The brick pattern arrangement is by far superior to the non-brick pattern. The brick pattern has shown improved structural stiffness in comparison with the non-brick pattern.

LINEAR COMPONENT - 1:5 scale

Conclusion:

The addition of a protective mesh has resulted in a greater resistance of the inflatable element to over-pressure. The mesh and inflatable present a similar behavior to the car tire - car tube system. Detaching the patches presents a problem when the fabric walls are always attached to the guide rails. This system for the fabric walls has been currently abandoned. The alternative of attaching the fabric walls directly to the ground cable structure is being considered as a manual option.

GRASSHOPPER SIMULATION - linear component - the model for the component frame has been implemented in Grasshopper for added flexibility.