project C:PROTOTYPE

(→VALIDATORS) |

|||

| (193 intermediate revisions by 3 users not shown) | |||

| Line 5: | Line 5: | ||

=<span style="color:orange">PROTOTYPE</span>= | =<span style="color:orange">PROTOTYPE</span>= | ||

| + | ===<span style="color:orange">FINAL PROTOTYPE</span>=== | ||

| + | <div style="float: left; width: 580px; margin-right:10px; text-align:justify"> | ||

| + | [[File:1_front.jpg|580px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 580px; margin-right:10px; text-align:justify"> | ||

| + | <youtube width="620" height="393" right >II2mGEVFVrg</youtube> | ||

| + | </div> | ||

| + | |||

| + | |||

| + | <div style="float: left; width: 1200px; margin-right:30px; text-align:left"> | ||

| + | |||

| + | ===<span style="color:orange">RESEARCH CONCLUSION</span>=== | ||

| + | |||

| + | '''A, Prototype Archievement''' | ||

| + | |||

| + | 1, the overall behavior scheme is functioning | ||

| + | |||

| + | 2, the proposed materials have the desired performance | ||

| + | |||

| + | 3, the valve & component system achieves the desired behavior | ||

| + | |||

| + | 4, the generic component is strong and stiff when inflated | ||

| + | |||

| + | 5, the prototype fragment shows the possibility of creating variable size arches in direct relation to the overall concept and architectural implementation | ||

| + | |||

| + | |||

| + | '''B, Prototype Improvement''' | ||

| + | |||

| + | 1, the current connection between component should only provide one degree of freedom | ||

| + | |||

| + | 2, each component should have its own valve system; this will assure that the whole system is air - tight and provides for superior control | ||

| + | |||

| + | 3, the air connection between the PVC hose and the component should be air-tight in any position and detachable | ||

| + | |||

| + | 4, the thickness of the rubber tires should be greater than the current 2.5 mm; a greater thickness of 4 to 7 mm would achieve superior performance | ||

| + | |||

| + | 5, the material of the tires should be butil rubber instead of the current natural rubber; this would assure that every component share the same behavior | ||

| + | |||

| + | 6, the underside of the component - the spine - should be stiff but bendable in one direction | ||

| + | |||

| + | 7, the rubber tires should be custom made into linear shapes with custom dome-shaped cap ends | ||

| + | |||

| + | 8, the generic component should be bigger, in direct relation to its strength, stiffness and stability | ||

| + | |||

| + | |||

| + | </div> | ||

| + | <div style="float: left; width: 1200px; margin-right:5px; text-align:justify"> | ||

| + | [[File:inflatable_prototype_2.JPG|340px]] | ||

| + | [[File:inflatable_prototype_3.JPG|340px]] | ||

| + | [[File:inflatable_prototype_4.jpg|168px]] | ||

| + | [[File:inflatable_prototype_1.JPG|340px]] | ||

| + | </div> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | <br> | ||

<div style="float: left; width: 380px; margin-right:30px; text-align:left"> | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| − | ===<span style="color:orange"> | + | ===<span style="color:orange">MATERIAL PROGRESS</span>=== |

| − | ''' | + | '''Materials Research''' |

| − | + | '''- Inflatable Units''' | |

| + | 08 December 2011 | ||

| − | + | Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes. | |

| − | [[ | + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> |

| + | [[File:Tube001.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Tube002.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Tube003.JPG|110px]] | ||

| + | </div> | ||

| − | + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | |

| + | 16 December 2011 | ||

| + | Vulcanization process | ||

| − | [[File: | + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> |

| + | [[File:IMG_0810.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_0815.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_0823.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_0839.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_0871.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_0884.JPG|110px]] | ||

| + | </div> | ||

| + | </div> | ||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| + | 17 December 2011 | ||

| − | + | First test-units arrived. MTB - inner rubber tubes. Material thickness: 1.5mm , Length: 300mm - ..., Diameter: 70mm - ... | |

| − | |||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:tube.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:vulcanizationmaterials2.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:rubber-without-frame.JPG|110px]] | ||

| + | </div> | ||

| + | </div> | ||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| − | |||

| − | + | <youtube width="350" height="250" right >8s-AJDCgAPU</youtube> | |

| − | |||

| − | + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | |

| + | [[File:heidenaurubber.jpg|200px]] | ||

| + | </div> | ||

| − | |||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| + | </div> | ||

| + | 18 units Heidenau D21 natural rubber | ||

| + | Size: 21" 3.00-3.25 90/90, 80/100 | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | '''- Frame for Inflatable Units''' | ||

| + | |||

| + | 14 December 2011 | ||

| + | |||

| + | First test-sheets arrived. PVC Truck-tarp. Material thickness: 1.5mm , Length: 1600mm, Length: 1000mm | ||

| + | |||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:truck-tarp01.JPG|110px]] | ||

</div> | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:trucktarp02.JPG|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:truck-canvas.jpg|110px]] | ||

| + | </div> | ||

| + | </div> | ||

| + | <br> | ||

| + | <br> | ||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| − | |||

| − | |||

| − | + | '''- Connection System''' | |

| − | + | 60 units horizontal-connections <br> | |

| + | <u>45 unit vertical connections <br></u> | ||

| + | 105 connections - total | ||

| − | |||

| − | + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | |

| + | [[File:connection01.jpeg|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:connection02.jpeg|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:connection03.jpeg|110px]] | ||

| + | </div> | ||

| + | </div> | ||

| + | <br> | ||

| + | <br> | ||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| − | |||

| − | |||

| + | '''- Air Pressure System''' | ||

| − | <div style="float: left; width: | + | |

| − | [[File: | + | 70 m transparent PVC tubing (outer diameter=10mm)<br> |

| − | + | 18 clamps (on tube-valves outer diameter= 8mm)<br> | |

| + | 18 valves (distributor)<br> | ||

| + | 1 x 3 way distributor<br> | ||

| + | 1 x air compressor<br> | ||

| + | |||

| + | |||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:tubing.jpg|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:lv_1.gif|110px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 110px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Air-Compressor1.jpg|110px]] | ||

</div> | </div> | ||

<div style="float: left; width: 380px; margin-right:10px; text-align:justify"> | <div style="float: left; width: 380px; margin-right:10px; text-align:justify"> | ||

| − | [[File: | + | [[File:board_scheme.png|330px]] |

| − | + | </div> | |

| + | |||

| + | <div style="float: left; width: 380px; margin-right:10px; text-align:justify"> | ||

| + | [[File:flow_board_scheme.png|330px]] | ||

| + | </div> | ||

| + | |||

| + | |||

| + | |||

</div> | </div> | ||

| + | <br> | ||

| + | <br> | ||

| + | <div style="float: left; width: 380px; margin-right:30px; text-align:left"> | ||

| + | |||

| + | |||

| + | |||

</div> | </div> | ||

| Line 72: | Line 240: | ||

<div style="float: left; width: 780px; margin-right:10px; text-align:justify"> | <div style="float: left; width: 780px; margin-right:10px; text-align:justify"> | ||

| − | |||

| − | + | ===<span style="color:orange">1:1 MODEL PROPOSAL</span>=== | |

| − | |||

| − | |||

| − | + | For the 1:1 model a small portion of the structure will be build: a fragment of the strip that is anchored to the ground. | |

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:01-defl.jpg|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:01-infl.jpg|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:02-infl.jpg|200px]] | ||

| + | </div> | ||

| + | |||

| + | |||

<div style="float: left; width: 250px; margin-right:10px; text-align:justify"> | <div style="float: left; width: 250px; margin-right:10px; text-align:justify"> | ||

| − | [[File: | + | |

| + | [[File:shapes.png|230px]] | ||

</div> | </div> | ||

| − | <div style="float: left; width: | + | <div style="float: left; width: 320px; margin-right:10px; text-align:justify"> |

| − | [[File: | + | [[File:prototype-realization.jpg|500px]] |

</div> | </div> | ||

| − | |||

| − | |||

</div> | </div> | ||

| − | |||

| − | <div style="float: left; width: | + | <div style="float: left; width: 780px; margin-right:10px; text-align:justify"> |

| − | + | ||

| + | ===<span style="color:orange">PROTOTYPE PROGRESS</span>=== | ||

| + | '''Material Test''' | ||

| − | + | 19 December 2011 | |

| + | Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes. | ||

| + | |||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:proto01.jpg|200px]] | ||

</div> | </div> | ||

| − | <div style="float: left; width: | + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> |

| − | [[File: | + | [[File:proto02.JPG|200px]] |

| − | + | </div> | |

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:proto03.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:proto04.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:proto07.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:proto05.jpg|200px]] | ||

</div> | </div> | ||

| + | <youtube width="620" height="250" right >hGq3anfSq0c</youtube> | ||

| + | '''Cap Test''' | ||

| + | 22 December 2011 | ||

| + | A different end of the component was designed: a cap. The hugger will be sewn with a sewing machine, <br> | ||

| + | but for the scale model this is not always possible -> it is too small to put under the sewing machine. <br> | ||

| + | The new cap was tested and here under you can find the pictures. | ||

| − | + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | |

| + | [[File:Neutral_position.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Flat_2.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Maximum_position.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Caps.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:Close_up.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:P1160827.JPG|200px]] | ||

| + | </div> | ||

| − | + | <youtube width="310" height="250" right >QcdnXseA4r0</youtube> | |

| + | <youtube width="310" height="250" right >xzUaD1SfhBw</youtube> | ||

| + | |||

| + | |||

| + | '''Real size component test''' | ||

| + | |||

| + | 10 January 2012 | ||

| + | |||

| + | By several experiment result, we defined the final prototype materials and dimensions. <br> | ||

| + | By accumulating the experience of tested components, this testing component is in 1:1 scale to the final product. | ||

| + | |||

| + | |||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_1439.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_1447.JPG|200px]] | ||

| + | </div> | ||

| + | <div style="float: left; width: 200px; margin-right:10px; text-align:justify"> | ||

| + | [[File:IMG_1445.JPG|200px]] | ||

</div> | </div> | ||

| + | |||

| + | <youtube width="310" height="250" right >lMXsHxhYsq8</youtube> | ||

| + | |||

| + | <youtube width="310" height="250" right >Z-0cizKZra4</youtube> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | </div> | ||

<div style="float: left; width: 1200px; margin-right:10px; text-align:left"> | <div style="float: left; width: 1200px; margin-right:10px; text-align:left"> | ||

[[Project C:Home|go back to project page >>]] | [[Project C:Home|go back to project page >>]] | ||

| + | </div> | ||

</div> | </div> | ||

Latest revision as of 10:00, 2 February 2012

PROTOTYPE

FINAL PROTOTYPE

RESEARCH CONCLUSION

A, Prototype Archievement

1, the overall behavior scheme is functioning

2, the proposed materials have the desired performance

3, the valve & component system achieves the desired behavior

4, the generic component is strong and stiff when inflated

5, the prototype fragment shows the possibility of creating variable size arches in direct relation to the overall concept and architectural implementation

B, Prototype Improvement

1, the current connection between component should only provide one degree of freedom

2, each component should have its own valve system; this will assure that the whole system is air - tight and provides for superior control

3, the air connection between the PVC hose and the component should be air-tight in any position and detachable

4, the thickness of the rubber tires should be greater than the current 2.5 mm; a greater thickness of 4 to 7 mm would achieve superior performance

5, the material of the tires should be butil rubber instead of the current natural rubber; this would assure that every component share the same behavior

6, the underside of the component - the spine - should be stiff but bendable in one direction

7, the rubber tires should be custom made into linear shapes with custom dome-shaped cap ends

8, the generic component should be bigger, in direct relation to its strength, stiffness and stability

MATERIAL PROGRESS

Materials Research

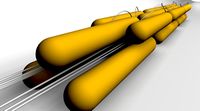

- Inflatable Units

08 December 2011

Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes.

17 December 2011

First test-units arrived. MTB - inner rubber tubes. Material thickness: 1.5mm , Length: 300mm - ..., Diameter: 70mm - ...

18 units Heidenau D21 natural rubber Size: 21" 3.00-3.25 90/90, 80/100

- Frame for Inflatable Units

14 December 2011

First test-sheets arrived. PVC Truck-tarp. Material thickness: 1.5mm , Length: 1600mm, Length: 1000mm

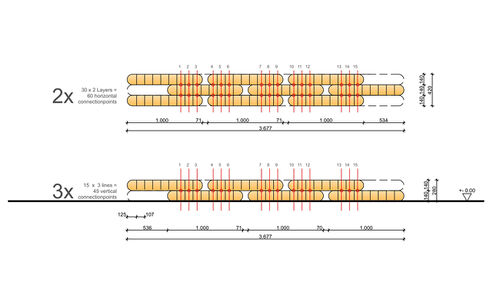

- Connection System

60 units horizontal-connections

45 unit vertical connections

105 connections - total

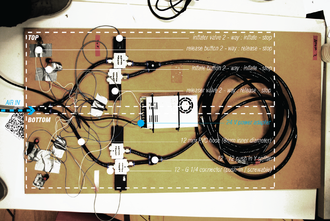

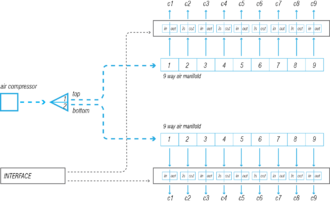

- Air Pressure System

70 m transparent PVC tubing (outer diameter=10mm)

18 clamps (on tube-valves outer diameter= 8mm)

18 valves (distributor)

1 x 3 way distributor

1 x air compressor

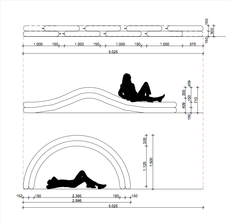

1:1 MODEL PROPOSAL

For the 1:1 model a small portion of the structure will be build: a fragment of the strip that is anchored to the ground.

PROTOTYPE PROGRESS

Material Test

19 December 2011

Visiting the Vehicle maintenance service(Van KLEEF)company in Delft for advice on vulcanization on vehicle tubes.

Cap Test

22 December 2011

A different end of the component was designed: a cap. The hugger will be sewn with a sewing machine,

but for the scale model this is not always possible -> it is too small to put under the sewing machine.

The new cap was tested and here under you can find the pictures.

Real size component test

10 January 2012

By several experiment result, we defined the final prototype materials and dimensions.

By accumulating the experience of tested components, this testing component is in 1:1 scale to the final product.