project G:Different systems

| Line 113: | Line 113: | ||

- needs to 'reset' for change in lay out. | - needs to 'reset' for change in lay out. | ||

| + | |||

| + | |||

| Line 121: | Line 123: | ||

Due to the different atractors in the motor, it can be controlled within a rotation of two degrees. | Due to the different atractors in the motor, it can be controlled within a rotation of two degrees. | ||

The second advantage of these motors are their size and strength. | The second advantage of these motors are their size and strength. | ||

| + | |||

[[File:Stappenmotor.jpg | 390px]] [[file:250px-StepperMotor.gif |390px]] | [[File:Stappenmotor.jpg | 390px]] [[file:250px-StepperMotor.gif |390px]] | ||

Revision as of 22:35, 30 November 2011

Contents |

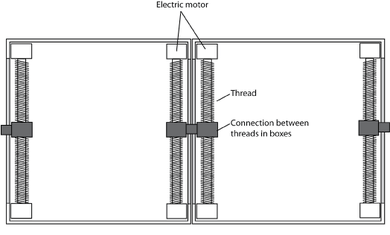

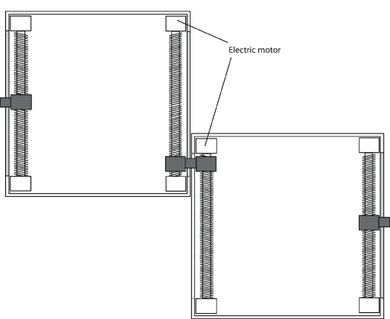

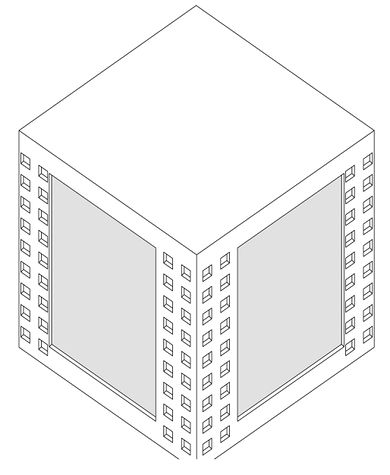

Actuators and threads

For this principle we use normal actuators. To give some indication a actuator with 1200n will:

- Have a size around 40mm*750mm

- Cost around 100 euro

- selflocking 800n

Advantages

- Small engines needed

- Simple principle

- Stabil/solid connections

- Big differences between neigboring elements possible

Disadvantages

- 4 Engines per box needed.

- Weight system

- Lot of chance of failure due to the number of engines.

.

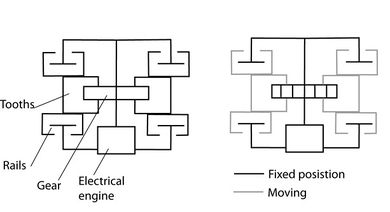

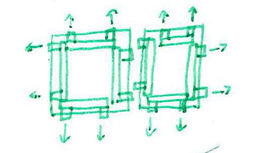

Gearing in between

Advantages

- Only 2 engines per box.

- Less weight due to less engines.

- Individual controlable

- Big differences between neigboring pistons possible

Disadvantages

- Connection is vulnerable.

- By failing element no more possibillity to move box

- Less load bearing

.

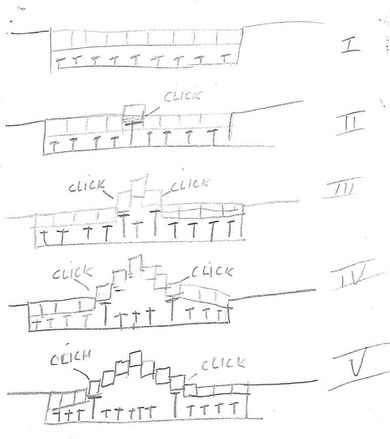

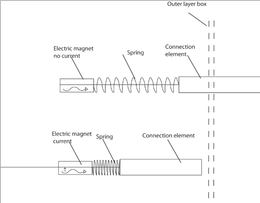

Clicking mechanism

Advantages

- Big actuators stay on the ground.

- Lightweight boxes

- Lot of space inside the box

Disadvantages

- 16 actuators per box needed.

- Vulnerable connections.

- needs to 'reset' for change in lay out.

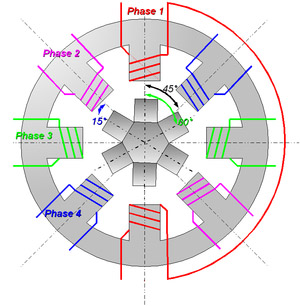

Motors

For this principle the best motors would be steppermotors. This motor can be controlled very precisely. Due to the different atractors in the motor, it can be controlled within a rotation of two degrees. The second advantage of these motors are their size and strength.

.