project H:Home

| Line 91: | Line 91: | ||

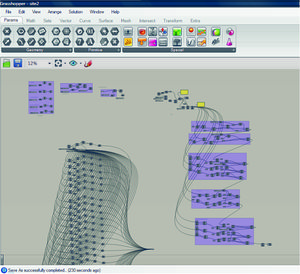

The parameters for our components are real time collected. We will place sensors on our components that will collect information which will be directly processed. | The parameters for our components are real time collected. We will place sensors on our components that will collect information which will be directly processed. | ||

| + | [[Project H:FABRICATION + ADAPTATION |read more >>]] | ||

</div> | </div> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[File:Components.gif| frameless | 940px | ]] | [[File:Components.gif| frameless | 940px | ]] | ||

Revision as of 20:01, 30 November 2011

BRIEF

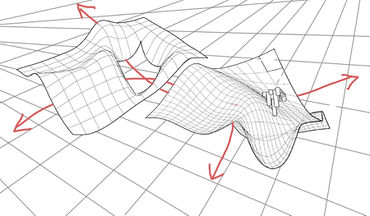

This project indicates a dynamic way of expanding from a flat surface into a fabricated system. The whole system shows different situations of density, which forms various spaces inside and outside. This dynamic system includes components, skins, structures and illustrates a smooth change in the fabrication of architecture. Users would treat this not only as constructed object but also as an integral enhancement of the site. Our concept "Symbiosis" in a way reflects this very phenomenon.

This project begins with an investigation into topological surfaces, different modules will be developed that could function both as surface and structure. The developed modules will allow for numerous connection combinations which enables behavioral characteristics within the system including, bending, torquing, flipping, splitting, and lifting by alternating component connections/ units and scale in order to adapt to various site parameters like user density, sun, wind, precipitation and noise. At some parts components morph into flat panels which merge with the ground. This will allow the system to act both as floor, wall, and roof, while blurring the lines between these conditions.

This project begins with an investigation into topological surfaces, different modules will be developed that could function both as surface and structure. The developed modules will allow for numerous connection combinations which enables behavioral characteristics within the system including, bending, torquing, flipping, splitting, and lifting by alternating component connections/ units and scale in order to adapt to various site parameters like user density, sun, wind, precipitation and noise. At some parts components morph into flat panels which merge with the ground. This will allow the system to act both as floor, wall, and roof, while blurring the lines between these conditions.

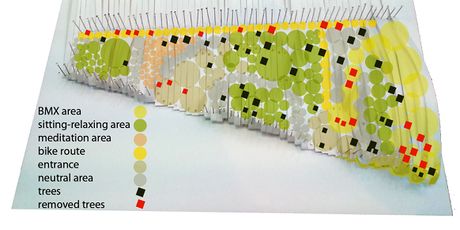

INTERVENTION

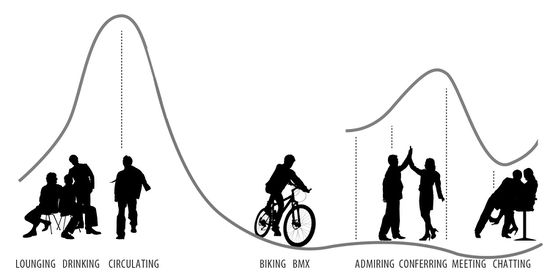

Our intervention will be a path through the park linking different uses. These uses will be walking, cycling, skateboarding, lounge area’s indoors and outdoors. This path will be a three-dimensional spatial structure that is shaped/molded/wrapped/warped according to the use. The structure will be interactive with its environment and its users. The primary task of such a structure as providing a sense of semi-enclosed space for people, alone or in groups, to feel comfortable while sitting, eating, transiting, conversing and/or reading along it.

Linkages are conceived to allow for almost constant spatial experience when switching from one path to another. The user is in a state of constant arrival to the same destination repeatedly and this view is mediated and controlled by the imposed view angle of the space, enclosure, openings and speed of motion. While performing the intervention, we need to take into account few other factors as well, like:

Linkages are conceived to allow for almost constant spatial experience when switching from one path to another. The user is in a state of constant arrival to the same destination repeatedly and this view is mediated and controlled by the imposed view angle of the space, enclosure, openings and speed of motion. While performing the intervention, we need to take into account few other factors as well, like:

[exploring the design, rules and functioning of a multi component system in detail]

[exploring temporal structures]

[creating a place of linkage within the urban void]

[instrument for activating the present landscape]

[material/component re-usability or extension after completion of structure's life cycle]

MULTI-COMPONENT SYSTEM RESEARCH

Our specialization is “multi component system”. We are trying to make components that can adapt (move, rotate, change color, etc.) by using real time information provided by sensors. In our specialization we search deep to find the optimal shape for these components within several conditions.

Mapping will be used as a tool to identify the patterns and understand them. It explains the found information to our validators as well.

PATTERNS AND GEOMETRY

We experiment with patterns which generally find references to the nature. A self-organization pattern as the one we will use is dynamic and gets developed over time. Based to the principles of self-similarity (the fundamental principle of a self-similar structure is the repetition of a unit pattern on different size scales), we can create a structure which theoretically can be extended to infinity and to adapt to every site.

PARAMETERS

For our project we are collecting two kinds of parameters.

To create our structure we are collecting parameters from the site and its environment. We are using the average value of the wind and sun seen over a year. Further we collect information from the existing pathway and linkages.

The parameters for our components are real time collected. We will place sensors on our components that will collect information which will be directly processed.

INTRODUCTION

There are two branches in physics that were explored separately in this stage.

Kinematic is a branch that studies different movement of body parts in relationship to its joints without considering the external forces that are needed to activate the movement.

Kinetic is a wider branch in a sense that this branch is concerned with not only the motion of bodies but also the forces needed to cause motion. In the case of architecture, kinetic can become very complicated. Computerized software and hardware will then need to be synchronized to achieve this goal.

METHODS AND TECHNIQUES

There are different methods and techniques to develop responsive architecture. We have tried to experiment with some of these systems.

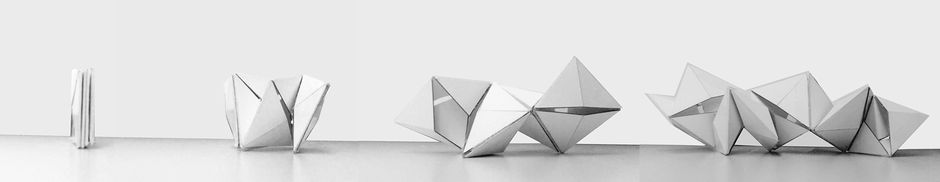

FOLDING

As a generative process, folding architecture is an experimental system. The relationship between each crease, fold, score, and cut give an infinite possibilities for form and function. Origami is the traditional Japanese form of paper art. This basic system is only using mountain folds (fold up) and valley folds (fold down). When origami changes to a larger scale, folding is no longer applicable. We then use rigid sheets and hinges. In this case, it is not required for the structure to start as a flat surface. This branch of origami is called “rigid origami” also named “Deployability”.

HYBRID SYSTEM

A Hybrid system is the integration of two or more different systems which otherwise have not been previously used within a single system. In the rest state, the material has no structural capacity, however, when in a pretension form through geometric formation the material works as a structural membrane supporting its own weight. Pre-tensioning the material changes its property and helps to store some energy which can later be used in correlation with various mechanical actuators. As a result, the exchange communication between the material, sensors and actuators creates a dynamic hybrid system with emergence behaviour.

EVALUATION AND PROPOSED METHOD

The System Branching

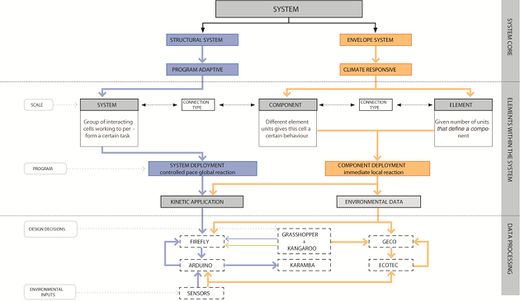

This diagram explains the methods and techniques that will be applied though out in order to achieve a “Responsive Kinetic System”. As previously noted, there are two different categories that will be examined. First, a Structural Responsive System capable of shape change in response to various functional needs. Second, an Environmental Responsive System that transforms based on several environmental conditions. These two categories are studied simultaneously on separate explorations. Eventually, these two systems will merge as collective behavior; performing and complimenting each other as one compound system.

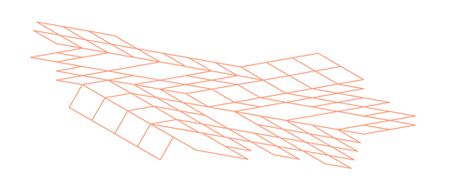

MODULAR PATTERNS

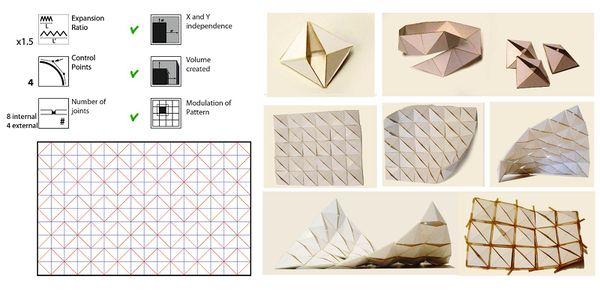

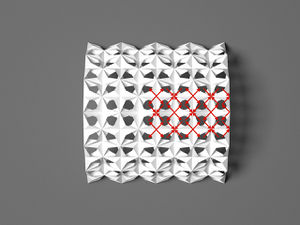

Knowing the strategy within simple patterns, we move onto more complex patterns. Modular patterns are usually asymmetrical; however, the patterns consist of smaller modular components that can be repeated on the surface. Modular patterns can be deployed to form different volumes while remaining as a surface when retracted. Due to its triangularity,

twisting and deformation is not visible at this scale. Modular patterns have a smaller ratio of expansion in the X and Y axis, however, they make up for it due to their greater volumetric expansion. From experimenting with the paper model, it seems that these patterns have the potential to control expansion independently from each other’s axis.

COMPLEX PATTERNS

The second type of patterns are the complex patterns which can be considered as difficult patterns when folding due to the variety of repetition from ridges and valleys from one point its immediate neighbour through faces. Once folded, the transformation of the surface is more difficult to control and to predict.

After exploring different patterns in this category, it becomes the most interesting due to the intricacy of the surface and the volume that it creates. Starting by holding the two sides, we can expand the surface by pulling it apart and at the same time create surface curvature on the other two sides. Its very flexible and deployable in nature. The only difficulty which we came across is the connection to the adjacent components.read more >>

EVALUATION AND SELECTION

From all of these pattern explorations, we selected a pattern. Using the concept of rigid origami, paper folding is replaced by rigid surface panels and joints for greater force resistance and structural integrity. To test this, larger scale models are required.

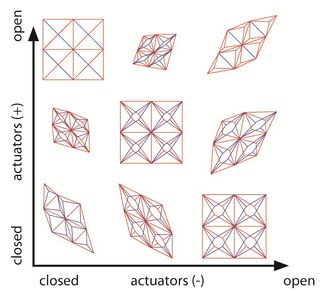

This MODULAR pattern component was chosen due to its expendability, control points, modularity, and the ability to create volume. From our previous hypothesis, it is important to check the expansion depending on X axis and Y axis. Because this surface transforms from a surface to a volume, we can conclude that it exhibits high potential to generate architectural spaces.

Positive aspects:

1)Independent control on each direction resulting in more form possibilities.

2)To control local displacement, 2 actuators per component are needed.

3)Non-triangulated elements increase the possibility of non-planar elements.

Negative aspects:

1)Complex system connections irrespective of simple local actuation principles

2)Integration

GEOMETRIC ANALYSIS

Nine different component geometries obtained by the combination of 3 stages in the actuators: open, semi-open and closed.

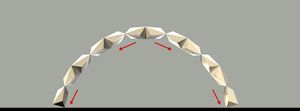

SECTIONAL ANALYSIS

Sections of the surface when activated in 2 different ways by local components reflecting curvature change in the global geometry.

GLIMPSES OF THE POPULATED COMPONENT GEOMETRY

KINETIC ACTUATOR AND CONTROL

In a kinetic system, there are two main ways of controlling motion; one being local control and another one being global control.

In global control, movement or displacement is defined by a single processor. As a result, several configurations and movements may be achieved. For instance, if an element is designed to move along the X, Y, and Z axis, it is more likely to do so within same formation every time it is activated. Therefore, the sequence of motion would not be adaptable to other sequences under different conditions.

On the contrary, systems with local control are most likely to have multiple processors and actuators. This means that each processor acts as a parameter that is uniquely designed and engineered to respond to one particular condition. When assembled together, different parameters will behave as one collective behaviour. This characteristic makes a system versatile and able to adapt to several different conditions.

KINETIC: SURFACE CONTROL

Through digital and physical model explorations, we are trying to prove that component becomes the most successful for independent control.

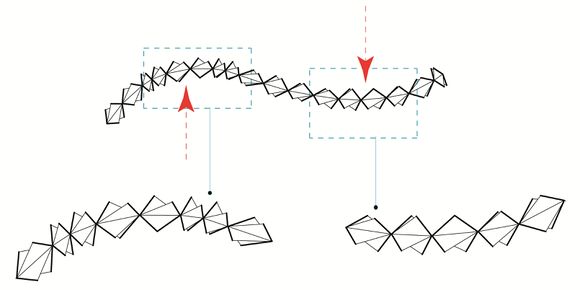

Local control - digital exploration

In order to gain local control, we begin by testing a foldable surface in terms of its components. At first, these components are studied as a two-dimensional surface which begins to change shape not only from its components but also from its own boundaries . This shape change is possible by controlling the aperture percentage from one component to the next. In return, being able to expand or contract the surface in some areas more than others. However, it is important to make note that there is always a sequence or a pattern that follows depending on which component becomes actuated before the others, and also depending on the location of this component within the surface area. In other words, there is a relationship between expanding or contracting depending on the aperture sequence from one component to the next.

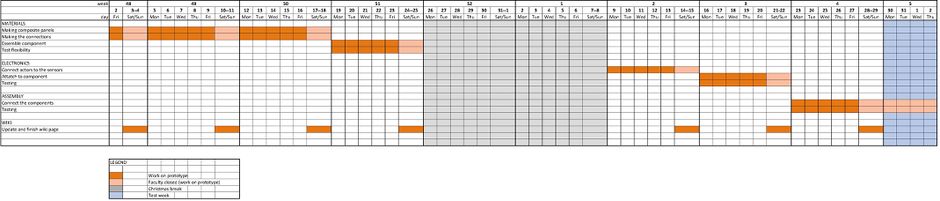

REALISATION PLAN

DETAILS

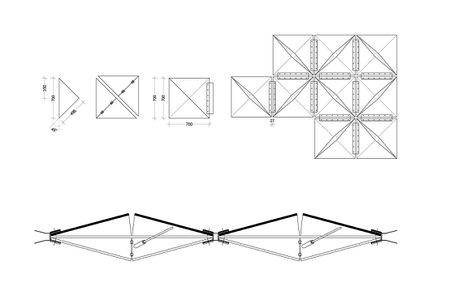

The fabricating process will start by cutting the wood into triangles. The connections between the panels of a component will be made by piano-hinges. For the connections between the components we will use bicycle tires. These tires will be bolded to the panels and glued together to form the connection and to create a hinge for the panels. Each component will have two actuators which will be attached on the inside of the component. They form a diagonal connection between the joints so that when activated both sides of the component will open.

The fabricating process will start by cutting the wood into triangles. The connections between the panels of a component will be made by piano-hinges. For the connections between the components we will use bicycle tires. These tires will be bolded to the panels and glued together to form the connection and to create a hinge for the panels. Each component will have two actuators which will be attached on the inside of the component. They form a diagonal connection between the joints so that when activated both sides of the component will open.

TIME-LINE AND MATERIALS

Many of the materials we use for fabricating the prototype are used materials. We are using bicycle tires, wood from billboards and second hand hinges. The fixings will be made by bolts and nuts. With this we are able to connect and disconnect the components for transportation to another site.

STRUCTURE

Our load bearing structure will be created by the component itself. When a component opens it is deforming, the outlines change. What first seemed to be the biggest challenge of our component, became very useful. When the component changes its outlines it creates tension in the components surrounding it. By anchoring the outlines of the structure and opening the components we can create a stiff structure. By adjusting the size of the openings by the actuators we can control the shape. read more >>

RELATIONSHIPS

ATOMS

Still our atom is in his origin state no collaboration has taken place. As to the relations to other atoms, atom 3 is on the same level with their component. The research we both did is quite different, but the outcome shows similarities .

PROJECTS

Project G is making a platform that can adjust to different functions. This concept is completely different than ours but the similarities are in the components. They also have designed one component they use repeatedly. Making a complex structure out of simple components.

VALIDATORS

STUDENTS BK: Wouter Kroon, Ifigenia Dimitrakou, Vladimir Ondejcik , Terry Pater

RESIDENTS STUDENT DWELLING: Ramon Rodrigo

ARCHITECTS: Spiros Papadimitriou (Spiros ip architecture,Thessaloniki)