project F:Realisation

| Line 3: | Line 3: | ||

{{project_F:Realisation-c}} | {{project_F:Realisation-c}} | ||

| + | |||

{{project_F:Realisation-e}} | {{project_F:Realisation-e}} | ||

| + | |||

{{project_F:Realisation-b}} | {{project_F:Realisation-b}} | ||

| + | |||

{{project_F:Realisation-a}} | {{project_F:Realisation-a}} | ||

| + | |||

{{project_F:Realisation-d}} | {{project_F:Realisation-d}} | ||

Revision as of 01:36, 1 December 2011

Design Realisation Relationships

Design Execution Prototype Validation Arduino development 1:1 Prototype

Contents |

Technical implementation

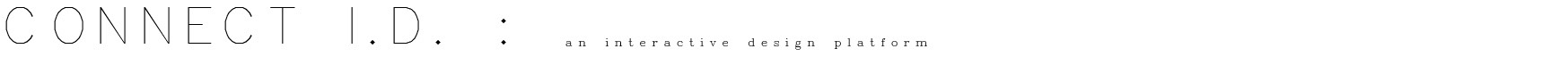

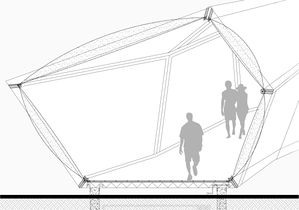

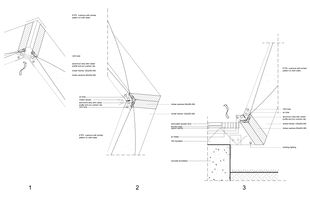

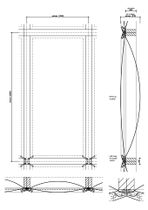

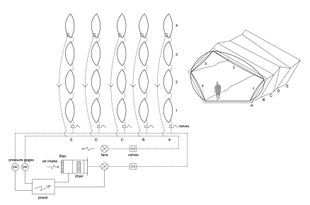

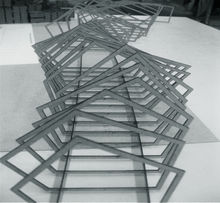

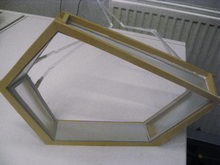

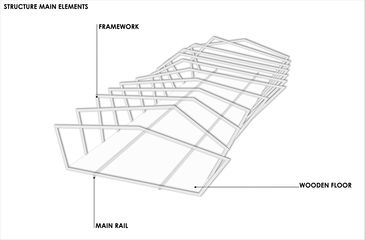

The overall design construction is based on the wooden ribs of the structure, stabilized by wooden cross beams to which the cushions will be connected. The frames are fixed on two concrete bases to allow it to 'float' just above the park. As it's a standard frame mass customized, a Grasshopper plugin to Rhino can automatically generate these frames from the powerlines in the model.

3D frame setup and alignment, lasercut drawing for model of all the frames

3D frame setup and alignment, lasercut drawing for model of all the frames

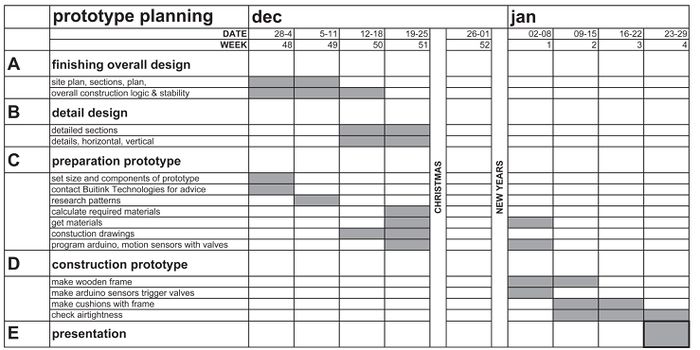

Timeline

The planning is set in four stages which partially merge at the beginning and end. This way we can always keep going.

In this third stage, we don't have to re-invent the wheel. It is an existing technology that we wish to implement in a new way. The whole design needs to finalized in order to focus in on the extend of the 1:1 prototype. After having contacted Buitink Technologies already in phase 2, it could be a good option to contact Rink de Vries, who is their specialist on cushion technologies.

Then we need to be the research and development team to draw up the prototype, develop the pattern, write the Arduino code, calculate the required materials and build it.

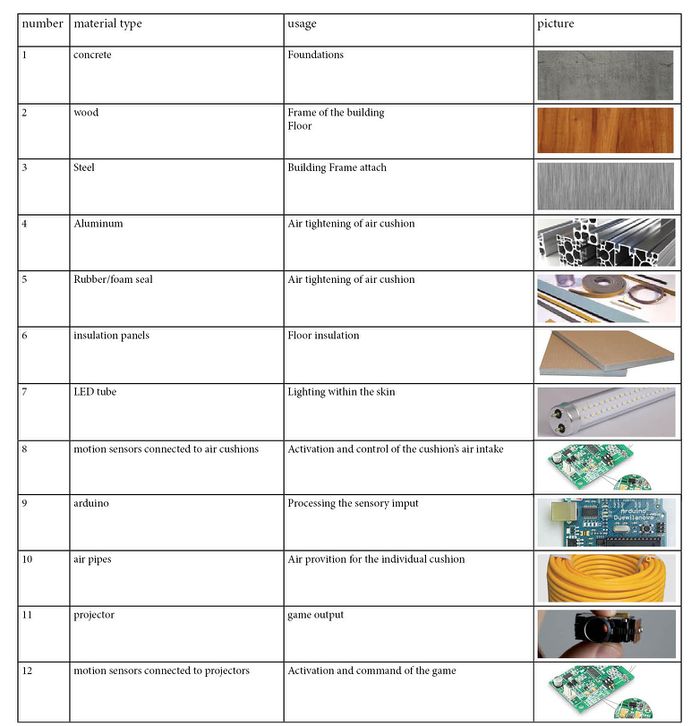

Materials and Equipment list

Prototypes

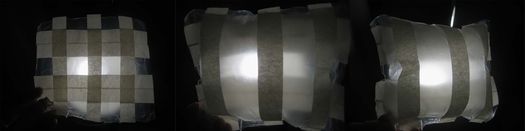

prototypes of cushion workings and cushion translucency.

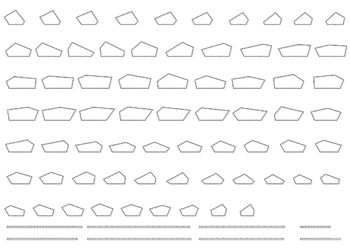

Pattern prototypes

Six prototypes of cushion patterns. Showing them in flat condition, blown up and at an angle to show how it changes with different angles of viewing.

The same six prototypes as in the video's in the three phases of experience: flat, blown up, and at an angle.

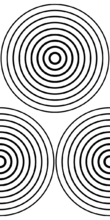

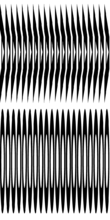

Experiements with moire effect and light patterns

- The moire effect causes an illusion of movement, where the patterns interfere

- Interaction of two differnt layers creates animation of shapes, even these shapes are not visible on the skin.

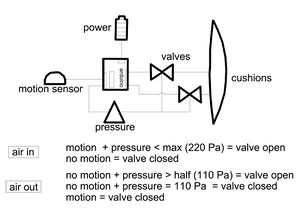

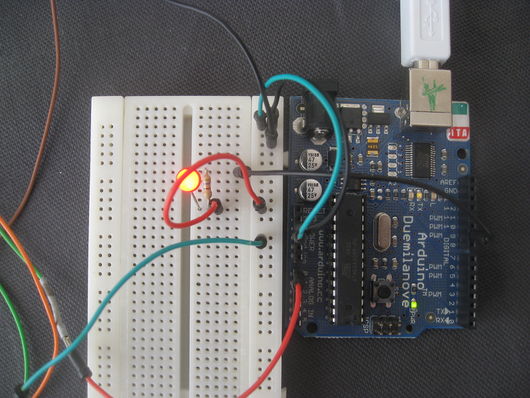

Arduino test

The cushions are Arduino controled via motion sensors.

This test shows that it's easy enough to control an on/off of something via motion sensors.

Technical validators

The Technical implementation is based on:

Florian Eckardt

Technology tutor, was one of the engineers on the Eden Project in England where ETFE air cushions made up the entire building.

He also wrote an article in 'Gevelbouw' on the Allianz Arena in Germany where ETFE cushions were used that are able to color the whole building.

Rienk de Vries Buitink Technology - sailmakers

Buitink Technology specialises in developing, manufacturing and delivering custom-made canvas, foil and technical fabric products. They have also facilitated in the fabrication of the Hyperbody HyperHumanHeart project.

On Thursday December 15th we have a meeting with him to discus the possibilities of how Buitink Technologies could assist us in our last stage of our design project. They will be able to provide us with vital information on detailing, structure, cushion information and possibly also fabrication possibilities.

Anette LeCuyer

She wrote the book ETFE - technology and design.

This is a book about the history of the architectural fabric and the current implementations of it. It has many example projects and details.

Walter Aprile

we would like to work with him to find the most appropriate arduino system.