project F:Realisation-g

Design Realisation Relationships

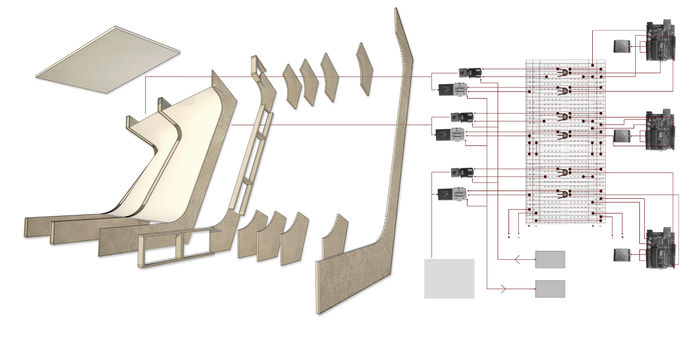

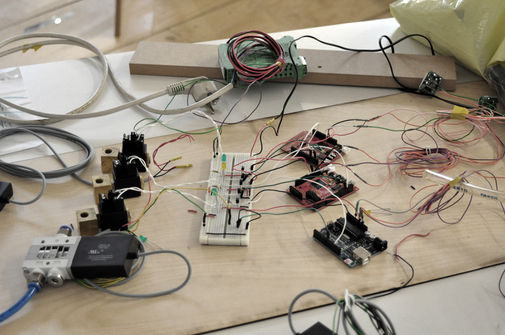

Design Execution Prototype Validation Arduino development 1:1 Prototype

Final Model

Prototype underconstruction

Prototype evalutation

Material and construction challenges

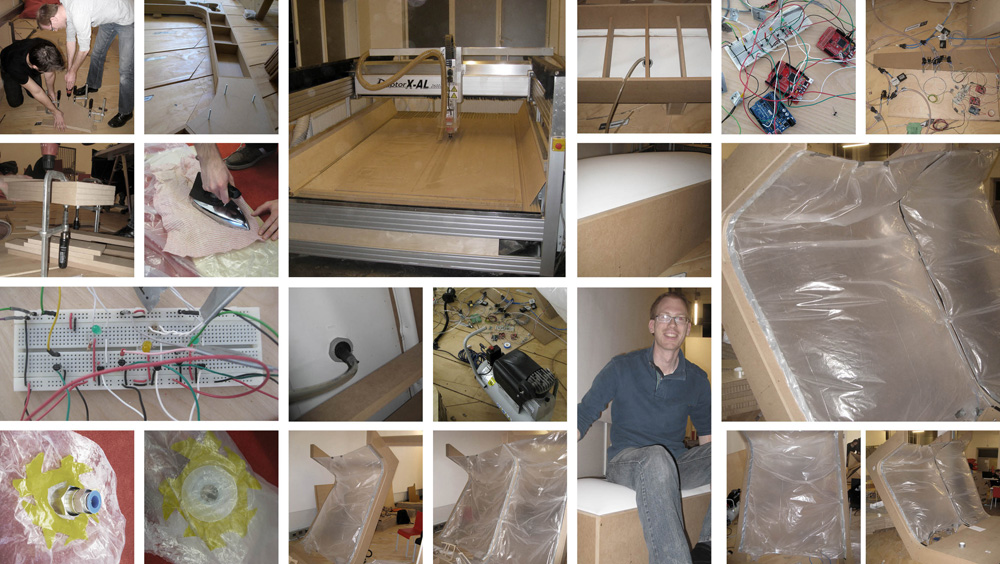

Cushion One of the challenges we faced was the stretch ability of the fabric for the cushion. The material that we planned on using at first was ETFE but after a meeting with Rienk de Vries at Buitink Technologies, we learned that it would take really a long time to change the amount of air in the cushions as the fragility of the material requires a small air input pressure. It also was not able to be inflated and deflated many times as it would lose it's characteristics of it's 30-40% stretchiness.

In order to still have a feeling of inflation and deflation of the ETFE, a pattern as illustrated in the project visuals could be made with 2 additional inner layers within the cushion. Yet as inflation and deflation (the experience of physical movement was more more important in the design) Rienk suggested semi-translucent stretchable fabric as an option but it would bevery challenging to weld together without a specific machine, plus it would require special valves to connect the tubing to the fabric which could hold the pressures building up inside. Apart from the fabrication limitations, the costs of about €16/m2 would be another hinder for us with the already big budget for the frames themselves.

In the end, the material of the cushion is a thick plastic sheet that we welded together using an iron into the needed shapes. Unfortunately, the school lost our order of air tubing and valves and we had to improvise a last minute solution for all the connections in and out of the cushions as well as to the valves with various diameters tubing ducktaped together for the final prototype.

The warped shape of the cushions in the end were a problem putting them into place as stretch folds were appearing where the cushions were not entirely parallel. In order to avoid this we folded the edges to shorten the cushions to get in line with the other side.

The prototype bench on which the stretch fabric has been put seems to work a lot better than the plastic cushions. Even though the fabric is only clamped inside the bench. The fabric stretches nicely and one can even sit on it. Proving the fabric has the interactive playful characteristics we were desiring for our building.

Structure The structure of the pavilion is a wooden laminated frame, however for the prototype we decided to construct a box-frame of several layers of 15mm MDF using screws, metal bars and bolts to keep it all together with laminated corners only. Due to the section of the structure built, the stability of the prototype became an issue. This was a problem specific to the prototype because in reality, the frame of the whole balances itself.

Electronic challenges

overall challenges and learning moments

Group dynamics, in which 4 people have to work together to come up with a problem, concept, challenge, and various models, are always an interesting case where some sort of collaboration / mutual agreements / compromises need to be made. Our group can really take away lessons from our experiences here. Also with 3rd party collaborations, having to rely upon them is not always a good thing. The university signed for, and then lost an important large package that held all of our connection pieces and tubing for our model. A free re-sending of the package was promised, but unfortunately never happened. This has provided us with the necessary insights as to be on time ordering materials to include possible problems. This is of course only a viable option when there is plenty of time, not when on a tight schedule and the prototype design is still developing. This has shown that early preparation in detail is very important to be able to get an overview of the WHOLE. how many m1 or m2 of everything is required. To make a shopping list for every part of the design to be able to act quickly and respond quickly to possible problems.

A big challenge for us was to find places to order these special materials, especially because we did not need 50m1 of tubing, but only about 10m1. Also valves and connection pieces are by the dozen, which quickly cause rising costs. In a professional situation quality is first and a whole list of manufacturers are known. We had to figure everything out ourselves. This caused people in the group to be more secretaries then anything, especially because you never find what you're looking for straight away, and need follow up on calls made.