project B:Design Plan

(→Research conclusions) |

(→Design) |

||

| Line 66: | Line 66: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 08:39, 1 December 2011

Team

And us:

Please use our feedback form and help us improve.

Public progress document

Follow us on Twitter: @HyberPublicNL

Our website (under construction) : www.HyperPublic.nl

HyperPublic : Theory: Home / Project B: Home

Research conclusions

Last weeks we have done a more thoroughly research about our topic. We interviewed multiple professors about their ideas on our topic of research. Also we got more information from the atoms through a discussion and a workshop. The results of these interviews and workshops, together with the old interviews are listed here

Some conclusions can be drawn from this research, which we need to take into account in order to make a proper design:

- We should find a common topic where the atoms relate to, use this as the topic for our design. Find related tools within this design.

- The tools we use in the design should be recognizable and easy to use by any user, no extra effort should have to be put into using the tool by the user, otherwise it will simple not be used.

- Use existing, standardized, software to build up your design. These are proven concepts and users can already identify with them. By merging multiple systems we can do something new.

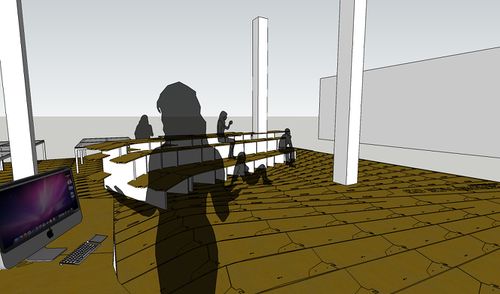

- In order to make collaboration work, there needs to be a physical element in the design, something multiple users can relate to and interact with.

- We have to create content ourselves, translate the needs of the user (atoms) to a certain tool. We should find the tools ourselves and master them in order to make a proper translation for the atoms. We should be an added value for the users.

Design

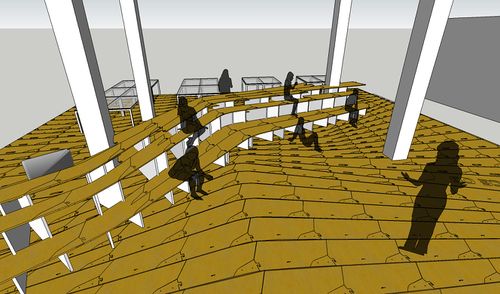

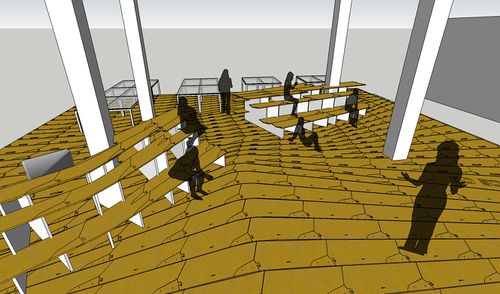

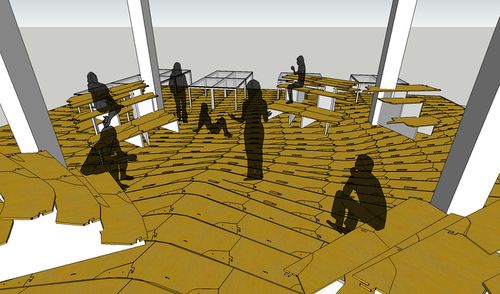

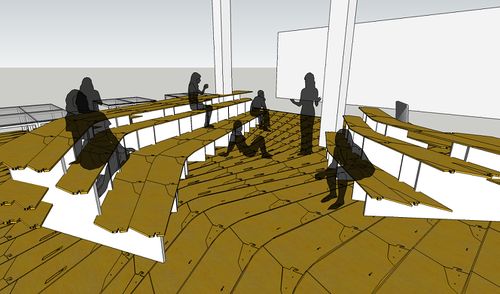

The design is capable of being moved and changed into different configurations according to the use of the space on the particular time.

HyperPublic : Project B: Home