project H:Pitch

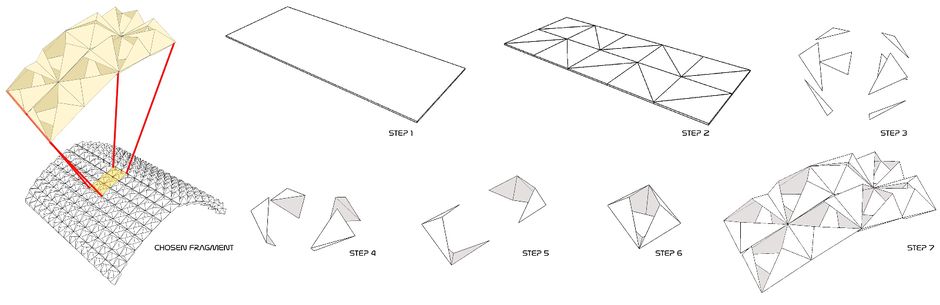

Flat surface into fabrication system

Process

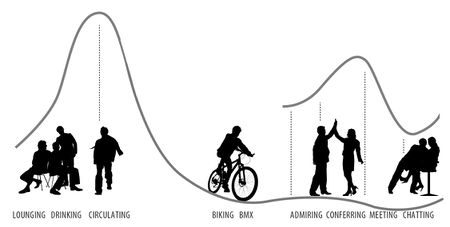

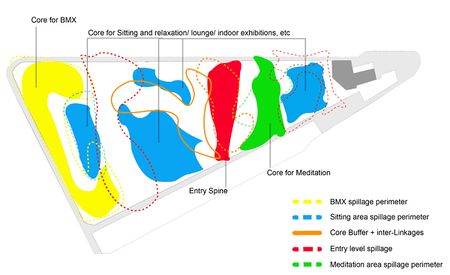

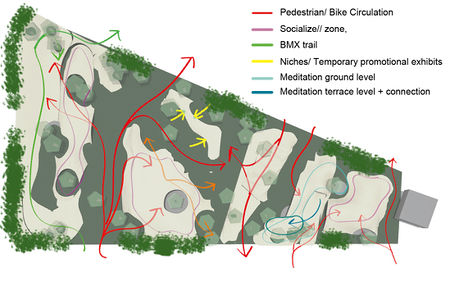

SPATIAL SPILLAGE

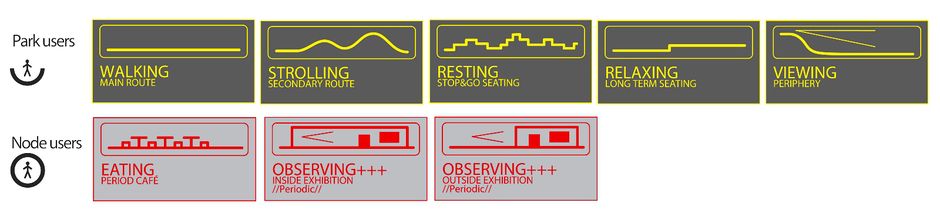

The surfology and its spatial types within the park topography afford the triggerings of activities within the programs of the park. These activities are of the temporal meaning that other activities can than be triggerd!

The surface inflections within each function are never tied to specific users or goods so they have capacity to change the organization of the activities taking place in them!

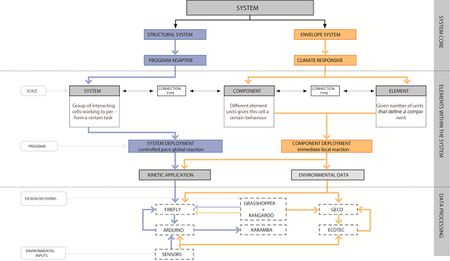

MULTI-COMPONENT SYSTEM RESEARCH

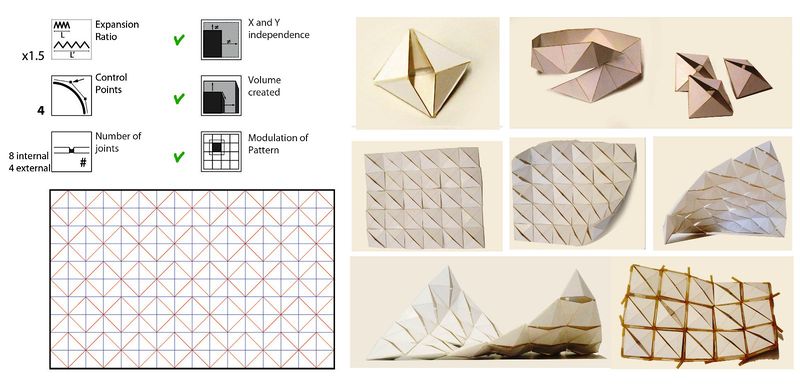

MODULAR PATTERNS

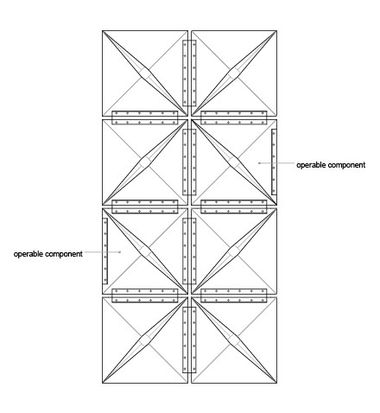

The patterns consist of smaller modular components that can be repeated on the surface. Modular patterns can be deployed to form different volumes while remaining as a surface when retracted. Due to its triangularity, twisting and deformation is not visible at this scale.

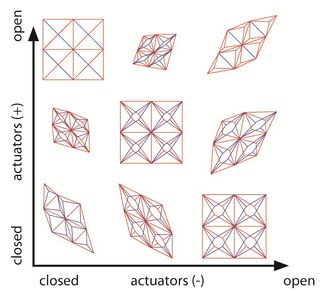

GEOMETRIC ANALYSIS

Nine different component geometries obtained by the combination of 3 stages in the actuators: open, semi-open and closed.

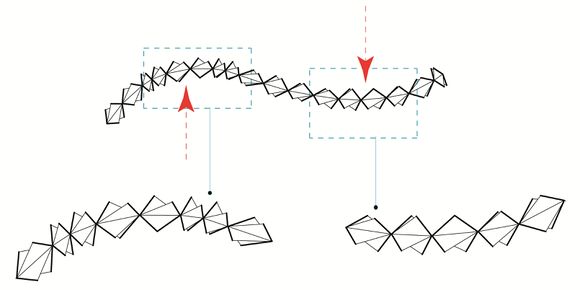

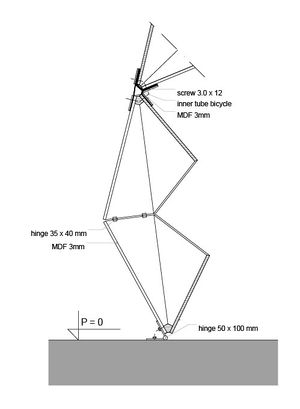

SECTIONAL ANALYSIS

Sections of the surface when activated in 2 different ways by local components reflecting curvature change in the global geometry.

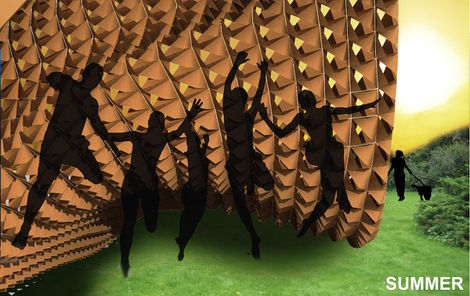

SEASONAL SCENARIOS

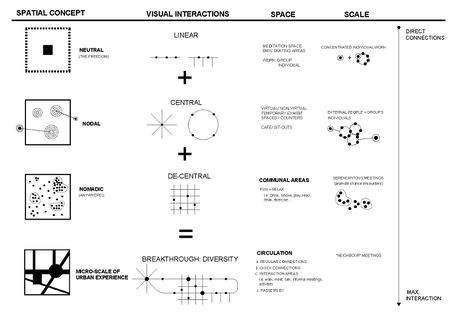

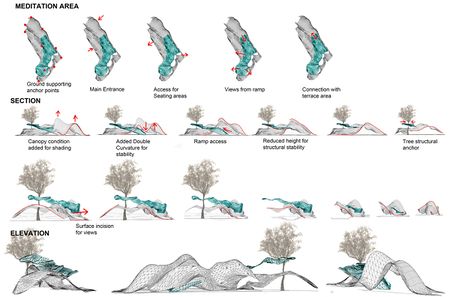

MEDITATION AREA

Existing trees been used as anchor points for the terrace structure, facilitating ambience for meditation space

Existing trees been used as anchor points for the terrace structure, facilitating ambience for meditation space

DESIGN CHALLENGE

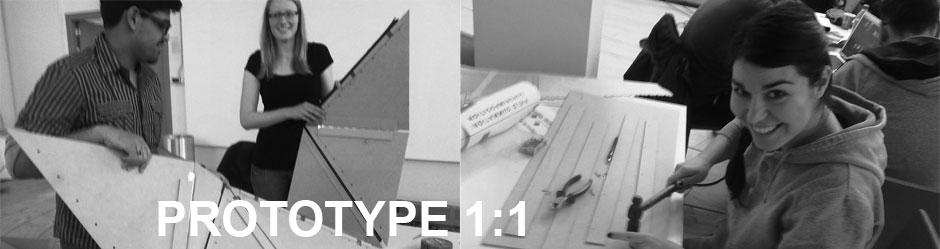

FABRICATION AND ASSEMBLY

In the assembly process of making 1:1 prototype, parts can be pre-assembled to step 5 for flat packaging using hinges in between. Parts from step 5 and step 6 are the only parts that need to be taken to the site for final assembly. With the 1:1 scale model, this arrangement create difficult to reach spaces and angles for the final assembly especially on verge of reaching step 7 where bike tire connections were required to be bolted. Constructing it on a desk/ studio is a challenge; however, constructing the final assembly on a real site is a different process that needs to be studied with further research.

In the assembly process of making 1:1 prototype, parts can be pre-assembled to step 5 for flat packaging using hinges in between. Parts from step 5 and step 6 are the only parts that need to be taken to the site for final assembly. With the 1:1 scale model, this arrangement create difficult to reach spaces and angles for the final assembly especially on verge of reaching step 7 where bike tire connections were required to be bolted. Constructing it on a desk/ studio is a challenge; however, constructing the final assembly on a real site is a different process that needs to be studied with further research.